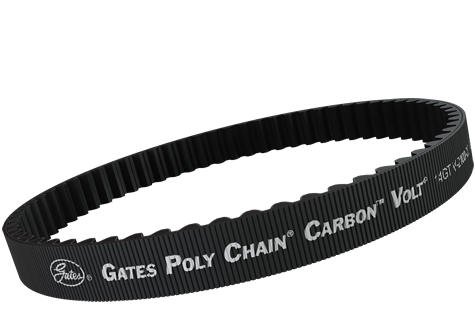

Poly Chain® Carbon™ Volt™

Durability that goes the distance

- Engineered with your safety in mind - The only belt on the market that meets the ISO 9563 standard over the lifespan of the belt. Patented static-conductive jacket construction transfers static electricity safely to carbon tensile cords, away from the driven side of the application.

- Cleaner, more compact drive solution - Offering zero maintenance and less downtime with no lubrication required – eliminating the risk of regulatory fines, contamination, and infected food handling spaces.

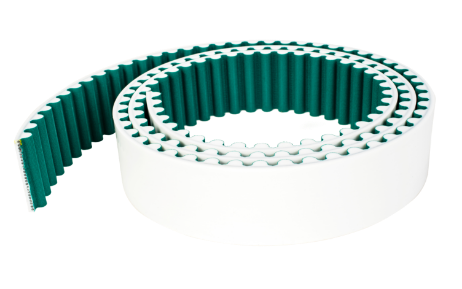

POWERGRIP™ GT4™

Powering performance in every application

- Engineered with advanced materials science - Delivering the highest power-carrying capacity and widest temperature range capability (-40°C to 120°C) of any belt in its class.

- Improved performance in automation applications - Reducing drive width with narrow belt and improved ergonomics that require no lubrication or re-tensioning.

- New standard lengths - Range extended with 14 additional belt length sizes.

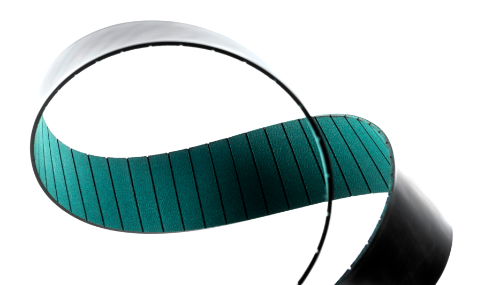

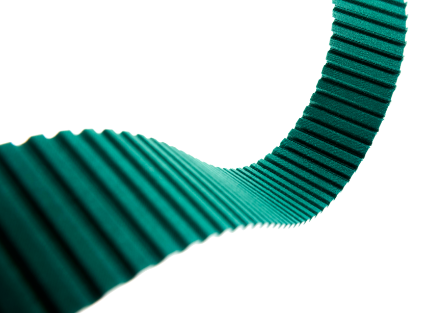

SYNCHRO-POWER™ LINEAR

Precision perfected for a broad spectrum of demanding applications

- Exceptional performance, robust and ready - Synchro-Power™ Linear can be configured for precise motion control applications.

- Optimised cost of ownership - Lighter weight and smaller pulleys and safe weight and cost for the drive system for less energy consumption and less cost of ownership.

- Endless possibilities - Unlimited customisation capabilities for any conveying challenge even down to -30°C to +50°C temperatures.

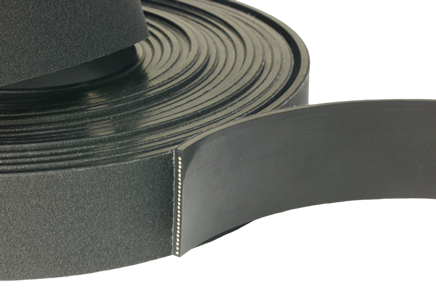

E-BELT

High tensile strength combined with transmission of electrical power and signals

- Ability to transmit electric power or signals - With exposed steel cords at the belt ends for electrical connector attachment, while incorporating the high tensile strength of the steel reinforcement.

- Multiple timing belt pitches and flat belts available - The open-ended e-Belts can be cut to custom length.

- Save on cost, save on space - Compact solution reduces the need for separate electrical cables and cable guiding systems.

SYNCHRO-POWER™ FLAT

High strength, low stretch for exceptional performance

- Operations optimised - High-strength durability of Synchro-Power™ Flat requires no maintenance, repair or overhaul. The polyurethane coating ensures increased belt life.

- Multiple possibilities - Various combinations of tensile member materials, several urethane grades and superior steel reinforcement, means you can handle the most demanding applications from lift systems, forklifts, to scissor-lift tables.

LIVE ROLLER BELTS

High tensile strength flat belt

- A durable solution for material handling systems - Designed not to stretch and does not require re-tensioning.

- Rollers driven by tangential friction belt - With lengths up to 150m and welded endless on the conveyor.

SYNCHRO-POWER™ FLEX

Truly endless construction for unlimited possibilities - up to 22.9m in length

- Superior strength - Extruded TPU, ideal for heavy load conveying and high-power transmission.

- Synchronous tracking - Handles specific application requirements with ease.

- Cutting-edge performance - Helically wound cords, resin grades and steel cord options available.

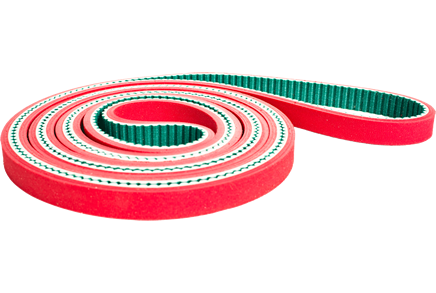

ENDLESS BELT WITH BACKINGS

Infinite possibilities

- Over 30 different backing material options - Range of customised solutions and design possibilities for both open-ended and endless timing belts.

- Chemical, oil & fat resistance - Available with FDA/EU food approval.

MEGASYS™ MXT™ and MXT™ With Xtratuff™ Plus Cover

Next-generation premium hydraulic hose

- Lightweight and up to 40% lower force-to-bend - Faster hydraulic fitting and easier cross-functional handling.

- Increased abrasion and ozone resistance - With robust Xtratuff™ plus cover, enabling you to work on diversified applications for longer.